Springs

Overview

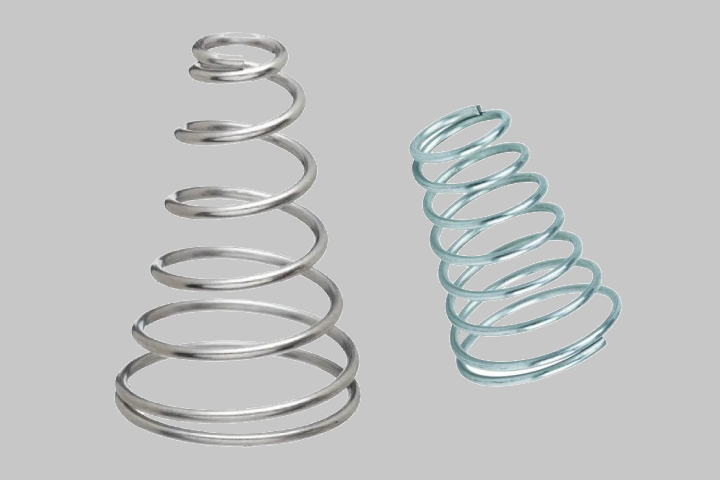

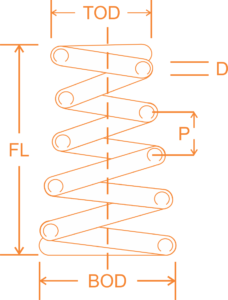

Conical springs are compression springs which are helically coiled round wires forming a tapered or conical shape. They are used to provide balance & reduce the solid height by the coils telescoping into each other. Conical springs are basically compression springs coiled in increasing or decreasing outer diameters thus making its shape a cone or tapered one. These springs tend to reduce solid height and provide stability. Conical Spring design enables each coil to fit within the next coil, which is a major advantage in applications where solid height is limited. It offers greater lateral stability that decreases the risk of buckling and the Uniform pitch reduces vibration and resonance.

Material:

- Spring steel is considered a general use steel because of its ability to be durable, yet flexible with a high degree of strength. It has the unique ability to be formed, shaped, and post heat treated, which makes it one of the premium choices for manufacturing springs for automotive, auto electrical and electrical applications.

- Stainless steel is good for corrosion resistant and Inconel is best for springs being used at very high temperatures.

- When it comes to springs that are required to be non-magnetic, Stainless Steel 316 can be used. This material type isn’t 100% non-magnetic though. Stainless steel 316 is only 90% non-magnetic.

Finish

Conical Springs are available in Nickel, Yellow and White Zinc Plating, Black Oxidizing, Lacquering, Green Passivation and Trivalent Passivation. Stainless Steel Springs are available with Bright Finish.

Manufacturing Process

Conical Springs are manufactured on imported CNC Spring Coiling Machines with SPC on line with free length sorting device for critical load value.

Testing & Certification Process

Each spring manufactured goes through a series of rigorous tests conducted on in house testing facilities such as Computerized Load Testing, UTS Testing, Torsion testing, Profile Projector amongst others. All springs are supplied with ROHS raw material compliant report. We also provide PPAP documents for automobiles and electrical industries as per requirement.

PRODUCT APPLICATIONS

Electrical contacts such as Push Buttons and Battery Contacts, Automobile Suspension Systems, Automotive Clutch Systems, Firing Mechanism of a Weapon, Medical Devices, Cell Phones, Large Stamping Presses and Lawnmowers, Motor Starter, Water Pumps, among other.

RELATED PRODUCTS

We offer wide range of 3 mm Conical Springs. These are widely used in automobile industry. Our offerings are of high quality and available at leading prices. We are appreciated for the highly efficient conical springs by our esteemed clients worldwide.

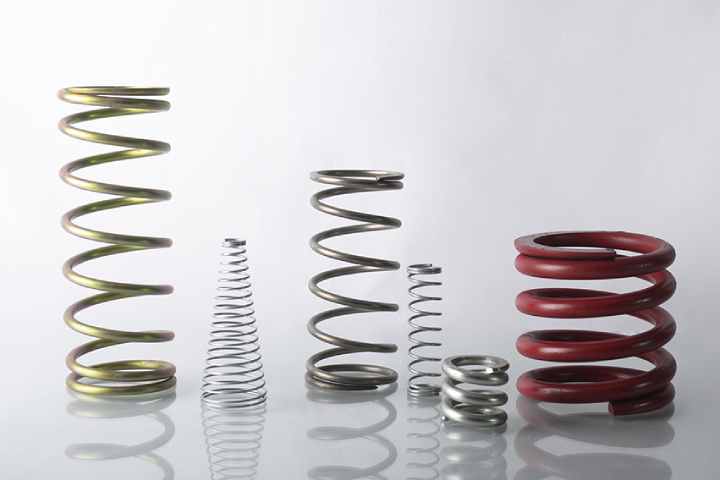

Wire forms come in all sorts of shapes & sizes and each play different role. Wire forms are wires that have been bent into specific shapes, often to fulfil a particular purpose, one can commonly recognize wire form as a spring; though any shape that a wire takes is technically a wire form, other often seen wire forms include hooks and certain types of clips.

Compression Springs are designed to operate with a compressive load in “Push Mode”. Compression Spring also has variable pitch between coils which are used to reduce solid height, buckling and surging to produce nonlinear load deflection characteristics.

Garter springs are essentially helical springs with connected ends; it forms a circle to provide a strong radial force. Garter springs are basically extension springs or compression springs whose ends are connected to make a garter belt that will exert force from its inner diameter.

Tension Springs/Extension Springs are helical wound coils, wrapped tightly together to create tension. Extension springs are springs which absorb and store energy by offering resistance to a pulling force.